3D Printed vs. Hand-Carved: Which Pet Figurine is Right for You?

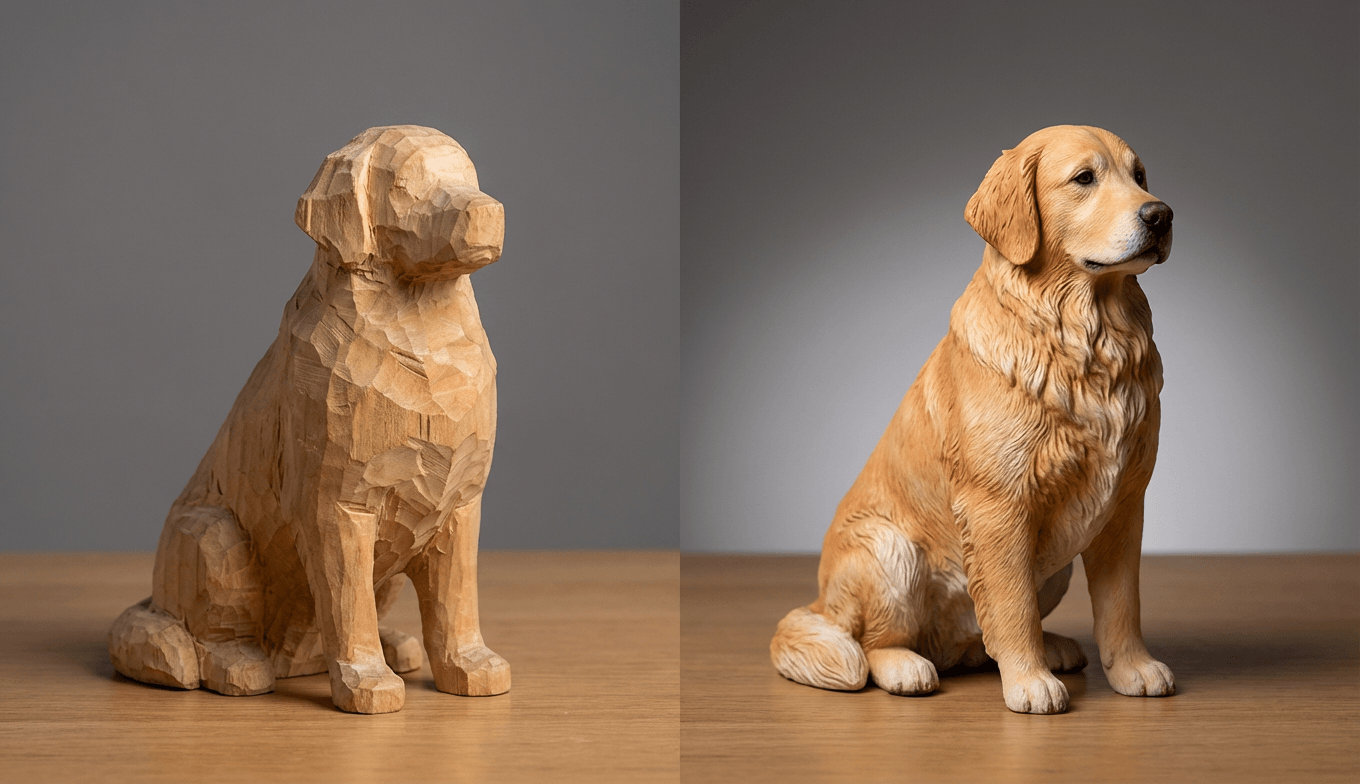

The morning light hit the mantelpiece just right, illuminating dust motes dancing around a small, wooden statue of a Golden Retriever. The wood was warm to the touch, smoothed by years of absentminded thumbs rubbing the ears—a habit that transferred seamlessly from the living dog to his memorial. Next to it sat something different: a hyper-realistic, full-color replica of a tabby cat, caught mid-stretch. It captured every whisker, every variation in her calico coat, down to the tiny notch in her left ear from a kittenhood scrap. One felt like a memory of spirit; the other felt like a moment frozen in time.

Choosing how to immortalize a pet isn't just about picking a product. It's about deciding how you want to remember. Do you want the artistic interpretation of their soul, or the uncompromising precision of their physical form?

Quick Takeaways:

- 3D Printing (SLA/DLP): Best for hyper-realism. Captures specific physical traits (scars, markings) with nearly microscopic precision using UV-cured resin.

- Hand-Carved Wood: Best for artistic warmth and durability. Focuses on the "essence" and posture rather than exact anatomical replication.

- Durability Factor: Wood ages gracefully and handles sunlight well; 3D printed resin requires UV protection and careful handling to prevent brittleness over decades.

- The "Uncanny Valley": 3D printing risks looking "too real" for some, while wood carving offers a stylized abstraction that can be easier on the grieving heart.

- Cost & Time: Hand-carving is labor-intensive (weeks/months) and unique; 3D printing is faster (days/weeks) but involves complex digital sculpting and post-processing.

The Engineering of Emotion: Understanding the Mediums

Most guides will tell you it’s a choice between "modern" and "traditional." That’s lazy. It’s actually a choice between subtractive and additive manufacturing, and that distinction defines everything about the final piece.

Subtractive Manufacturing: The Soul of Wood

When an artist carves wood, they are removing material to reveal the shape inside. It is a destructive process that creates creation.

Think about a block of Basswood or Tupelo. The artist looks at your photo, then looks at the block. They aren't trying to measure the exact millimeter distance between your dog's eyes. They are looking for the gesture. The way your Greyhound’s spine curved when she slept, or the specific alert tilt of your Terrier’s head.

Because wood has grain—a literal direction of growth—it fights back. The carver has to work with the material. This introduces a level of abstraction. You cannot carve a single whisker out of wood; it will snap. Instead, the artist suggests the whiskers through texture and shadow. This abstraction is powerful. It allows your brain to fill in the gaps with memories.

Additive Manufacturing: The Precision of Light

3D printing, specifically the kind used for high-end figurines (SLA or MSLA), is entirely different. We aren't cutting away; we are growing.

We use Stereolithography (SLA) or Masked Stereolithography (MSLA). Forget the cheap plastic spaghetti (FDM) printers you see in libraries. We use liquid photopolymer resin. A vat of liquid sits over a light source. A build plate descends, and UV light flashes a specific pattern—a single layer of your pet—curing the liquid into solid plastic.

The build plate lifts 0.05mm (that’s thinner than a human hair). It lowers again. Another flash of light. Layer by layer, your pet is pulled out of the primordial ooze of resin.

This allows for geometry that is impossible in wood. We can print the negative space between a bird’s feathers. We can print the hollow inside of a mouth. We can capture the texture of a wet nose. But this precision comes with a massive engineering overhead that most customers never see.

The Deep Dive: How 3D Printed Replicas Are Actually Made

We need to dispel the myth that 3D printing is a "press button, get statue" magic trick. It is a craft as demanding as sculpting, just with different tools.

1. The Digital Sculpt (The "Ghost" Phase)

Before a printer hums, a digital artist spends 10–20 hours in software like ZBrush. This isn't scanning. Unless you scanned your pet while they were alive (which is rare), the artist is sculpting from your photos.- The Trap: Photos lie. A wide-angle lens makes a nose look huge. A dark photo hides the muscle definition.

- The Fix: The artist has to understand anatomy. They build a skeleton, add muscles, then skin, then fur. They are translating 2D data into 3D space. If the artist doesn't know how a cat’s shoulder blade moves, the print will look like a stuffed animal, not a living creature.

2. Orientation and Supports: The Hidden Engineering

Once the sculpt is done, we don't just drop it into the printer software. We have to orient the model.If we print a dog standing straight up, the legs might be too weak to support the heavy body as it peels off the vat film during printing. We often tilt the model at 45 degrees. Then, we add supports—thousands of tiny scaffolding pillars that hold the model in place while it prints.

- Why this matters to you: If the engineer places a support on the tip of the nose or the center of the pupil, removing it will leave a pockmark. A veteran operator places supports in "shadow areas"—under the belly, inside the ears, under the tail—hiding the scars of manufacturing.

3. Hollowing and Suction

We rarely print solid resin. It’s heavy, expensive, and prone to cracking. We hollow the model out. But here’s the physics problem: if you print a hollow cup upside down and push it into liquid, you create a suction cup.The force of that suction can rip the model off the build plate. To prevent this, we drill invisible "drain holes" (usually in the paws or under the base) to let the liquid resin escape and equalize pressure. If you buy a cheap 3D print and it cracks six months later, it’s often because uncured liquid resin was trapped inside, slowly eating the shell from within.

4. The Post-Processing Gauntlet

When the print finishes, it’s covered in toxic, sticky goo. 1. Washing: It takes a bath in Isopropyl Alcohol to strip the excess resin. 2. Curing: The plastic is still "green" (soft). We blast it with high-intensity UV light in a curing chamber to finalize the chemical bonds. This is where the material gets its final hardness. 3. Sanding: Those thousands of supports? They are clipped off by hand, and every single contact point is sanded smooth. This takes hours.The Art of Finish: Paint vs. Stain

The biggest visual difference between the two mediums lies in how they handle color.

Wood: The Warmth of Stain

With wood, we often use semi-transparent stains or washes. The goal is to let the grain show through. If your dog had a black patch, we stain that area dark, but you can still see the life of the wood underneath.This creates a "living" texture. It feels organic. It warms to the room temperature. However, it cannot perfectly replicate complex patterns like the ticking on a Cattle Dog or the brindle of a Boxer. It suggests the pattern rather than documenting it.

3D Print: The Canvas of Reality

A cured resin print is usually grey or white. It is a perfect, smooth canvas.Artists use airbrushes for the base coats—creating gradients that mimic the way light hits fur—and fine brushes for the details. We can paint the reflection in the eye. We can paint the pinking of the skin inside the ear.

The "Aha" Moment: The realism of a 3D print comes from subsurface scattering*. Real skin and fur absorb light and bounce it around. Plastic is opaque. To make a figurine look alive, we have to paint it with translucent layers to fake that depth. A bad paint job looks like a toy. A great paint job looks like taxidermy without the creepy factor.

Durability and "Shelf Life"

This is the conversation nobody wants to have, but as engineers, we have to be honest about material science.

Wood is an heirloom.

We have wood carvings from the 16th century that look fantastic. Wood is stable. If you drop a wood carving, it might dent, but it rarely shatters. It handles sunlight reasonably well (though all color fades eventually). It is robust.

- Brittleness: If you drop a resin ear on a tile floor, it will snap. It is more like ceramic than plastic in terms of impact resistance.

- Temperature: Resin hates extreme heat. Don't leave a 3D printed figure in a hot car; it can warp.

The Verdict: If you want something your toddler can hold, or something to sit in a sun-drenched window, go with wood. If you want a piece that sits safely in a display cabinet or on a shelf away from direct sun, resin is perfectly fine.

The "Uncanny Valley" and Grief

Here is the psychological angle that tech specs don't cover.

We had a customer, let’s call her Sarah. She lost her Border Collie, Max. She ordered a high-end, full-color 3D print. When she unpacked it, she burst into tears—but not in a good way. She put it back in the box.

"It looks too much like him," she told us later. "But it’s not moving. It feels like... a shell."

This is the Uncanny Valley. When something is 95% realistic but 5% off (because it’s still), our brains register it as "wrong" or "zombie-like." For some people, hyper-realism is comforting. They want to see that specific scar. They want to look into the eyes and see the exact shade of amber.

For others, like Sarah, the abstraction of wood is safer. The wood carving didn't try to be Max. It represented Max. It allowed her to project her memories onto it without the jarring disconnect of a frozen, hyper-real body.

Ask yourself: Do you want to remember exactly what they looked like (3D Print), or how they felt (Wood)?

Cost and Turnaround: The Reality Check

Custom work is not cheap, nor should it be. You are paying for skilled labor, not raw materials.

Hand-Carved

* Time: 6–12 weeks. You cannot rush drying wood or hand-carving. * Cost: Generally higher ($300–$800+). You are paying for a sculptor's physical time. Every chip of wood is a decision. * Uniqueness: 100% unique. No two will ever be the same.3D Printed (Custom Sculpt)

* Time: 3–6 weeks. Digital sculpting is faster than physical carving, and printing takes hours, not days. * Cost: Moderate to High ($150–$500). The cost is front-loaded in the digital sculpting time. * Replicability: Once the file exists, you can print copies. This is huge for families. If you have three siblings who all want a memorial of the family dog, 3D printing is the only cost-effective way to do it. You pay for the sculpt once, and the prints are cheaper.Which One is Right for You?

Let’s break this down by personality type—yours and the pet’s.

- Markings Matter: Your Calico has a specific map of spots that defines her. Your dog has heterochromia (two different colored eyes).

- The Pose is Complex: You want a figurine of your dog catching a frisbee mid-air, or your cat intricately curled in a basket. Resin supports complex geometry that wood cannot.

- You Want Multiples: You need copies for family members.

- You Love Tech/Modern Aesthetics: You appreciate the crisp, clean lines and high-fidelity detail.

- Tactile Feel is Important: You want to be able to touch the figurine. The warmth of wood is soothing; resin feels like cold glass/plastic.

- You Prefer Impressionism: You want the spirit of the pet, not a forensic replica.

- Longevity is Key: You want an heirloom that requires zero maintenance and will survive a move without bubble wrap paranoia.

- Sustainability: You prefer natural materials over polymers.

A Note on "Hybrid" Options

We are seeing a fascinating trend in the custom figurines market: hybrid workflows.

Some artists now sculpt digitally (to get the anatomy perfect), print the model in a basic resin, and then use that print as a reference to carve the final piece in wood. Others print in wood-composite filaments (PLA mixed with sawdust), which can be stained like wood but printed like plastic.

While wood-fill PLA is interesting, it lacks the grain structure of real timber. It stains flatly. As purists, we believe if you want wood, get wood. If you want detail, get resin. The middle ground often compromises both.

Frequently Asked Questions

Can I put my custom pet figurine outside on a grave marker?

Short answer: No. Long answer: Neither standard resin nor indoor-finished wood will survive a year outdoors. Resin will yellow and crack from UV exposure and freeze-thaw cycles. Wood will rot or split. If you need an outdoor memorial, you need cast bronze or sealed stone. We have seen people try to seal 3D prints with marine-grade varnish, but moisture eventually finds a way in. Keep these treasures inside.My pet had a very specific underbite. Can 3D printing capture that?

Absolutely. This is where 3D printing shines. If you have a photo of the underbite, the digital sculptor can manipulate the mesh to pull the lower jaw forward exactly as much as needed. In wood, an underbite often looks like a mistake or a chip unless the carving is quite large. For dental specifics, go digital.How many photos do I need to send for a good result?

Quality beats quantity, but angles matter. We need: 1. Profile (Side view): To see the snout length and body shape. 2. Front on: To see eye spacing and chest width. 3. Top down: To see the markings on the back. 4. The "Quirk" shot: A photo of that weird thing they did with their ear or tail. Pro Tip: Try to take photos at the pet's eye level, not looking down from a human height. Looking down distorts the head-to-body ratio (the "bobblehead" effect).Is 3D printing bad for the environment?

It’s a valid concern. Resin is a chemical. However, custom manufacturing produces significantly less waste than mass production. We only print what is ordered. There is no inventory sitting in a warehouse. Furthermore, at PawSculpt, we recycle our isopropyl alcohol and cure our waste supports into inert plastic before disposal. Compared to the carbon footprint of shipping mass-produced stone statues, a lightweight, hollow resin print is relatively low-impact.Can you fix a broken resin figurine?

Yes, usually. Because it is a clean break (like ceramic), it can often be repaired with a tiny dot of cyanoacrylate (super glue) and a steady hand. Wood is harder to repair invisibly because glue doesn't absorb stain the same way the wood fibers do.The Final Polish

I keep a small box of "failed" prints in my workshop. A paw here, a tail there. Sometimes I pick one up and marvel at the fact that we can turn liquid and light into a physical object that makes someone cry happy tears.

Whether you choose the additive path of resin or the subtractive path of wood, you are doing the same thing: you are acknowledging that a life mattered.

The "right" choice isn't about the technology. It's about where you find the connection. If you close your eyes and picture your pet, do you see a photograph? Then choose 3D printing. Do you feel a presence? Then choose wood.

Whatever you choose, put it somewhere the light hits it. Let the dust motes dance. They’re still with you.